Why sequential numbering is essential for food safety & traceability

Ensuring traceability and compliance is essential for food manufacturers aiming to protect their consumers, brand and bottom line. In the complex arena of food production, maintaining complete oversight of every product batch, from raw material to final shipment, is no easy task.

That’s where sequential numbering comes in. By attributing a unique, traceable code to every batch, item or production cycle, food manufacturers can track products at every stage of the supply chain. This enables faster recalls, more accurate reporting and improved compliance with regulatory standards like HACCP, FDA and EU regulations.

In this guide, we’ll explore:

What sequential numbering is

Why it matters for food processors

How Detectamet supports sequential numbering with detectable products

Read on to strengthen your food safety processes, stay ahead of audits and improve traceability.

What is sequential numbering in food manufacturing?

So, let’s start at the top by understanding sequential numbering within the context of food manufacturing. Sequential numbering is the process of assigning a unique, incremental number to items, batches or production cycles. Unlike static barcodes or batch codes, sequential numbers provide a precise record of production history, enabling detailed tracking of each product or component as it moves through the production process.

For food manufacturers, sequential numbering is therefore a vital part of modern traceability systems. Each number acts as a unique ‘ID’ that links a product back to its production run, the time of manufacture and the materials used. This unique identifier allows manufacturers to locate, track and trace products in the event of a recall or quality issue.

How it works:

- Production run: each production batch is assigned a unique sequential number.

- Labelling: labels, tags or packaging are printed with this number.

- Tracking: as the product moves through the supply chain, the sequential number is used to track its location.

- Audit & recall: if contamination is detected, the sequential number allows affected products to be identified and removed efficiently.

This system is particularly important for products that are stored, transported and handled in large quantities, where a single defective batch can impact entire shipments.

Why is sequential numbering important for food processors?

The modern food industry operates under stringent regulations to ensure the safety, traceability and quality of food products. Sequential numbering provides a simple but powerful way to meet these requirements. Here’s why it matters for food processors:

Traceability & recall readiness

When contamination or a defect is detected, food processors must act fast. Sequential numbering allows companies to:

- Track affected batches: identify affected product batches quickly.

- Pinpoint the problem: determine the production time, line and source of the issue.

- Accelerate recalls: quickly isolate affected products, minimising business disruption and consumer risk.

Picture the scene: if a foreign matter contaminant - let’s say a pen lid - is found in a batch of bread, sequential numbers make it possible to recall only the affected items, not the entire product line. This prevents unnecessary product waste and reduces operational costs.

Regulatory compliance

Food safety laws, such as HACCP, FDA and EU food regulations, require complete traceability across production. Sequential numbering helps food processors meet these compliance obligations by providing a clear, verifiable production history for every product.

When regulatory authorities request information during an audit or inspection, processors can produce a full product history for any item. This not only ensures compliance but also builds trust with customers and regulators.

Inventory control & stock rotation

Sequential numbering supports ‘FIFO’ (First In, First Out) stock rotation, reducing waste and ensuring fresher products are shipped first. By tracking products through sequential numbering, warehouses and distribution centres can manage inventory more effectively. Key benefits include:

- Reduce product spoilage: ensure older stock is shipped before newer stock.

- Accurate stock control: maintain real-time oversight of available products.

- Minimise financial losses: waste reduction means higher margins.

Food safety & foreign matter contamination

Food contamination is one of the biggest risks for food manufacturers. With Detectamet's Metal Detectable & X-Ray Visible products, for instance, contaminants like fragments of pens, gloves or tools can be detected and traced. Sequential numbering adds another layer of protection by ensuring full product traceability.

This strengthens the food safety net and reduces the risk of a public health incident.

Customer confidence & brand protection

In the era of transparency, consumers demand to know where their food comes from. Companies that can demonstrate a strong traceability system are seen as more trustworthy. Sequential numbering provides clear evidence of quality control, product traceability and commitment to food safety.

How Detectamet supports sequential numbering for food processors

Detectamet offers a range of traceability products that enable food processors to implement sequential numbering systems across their production lines.

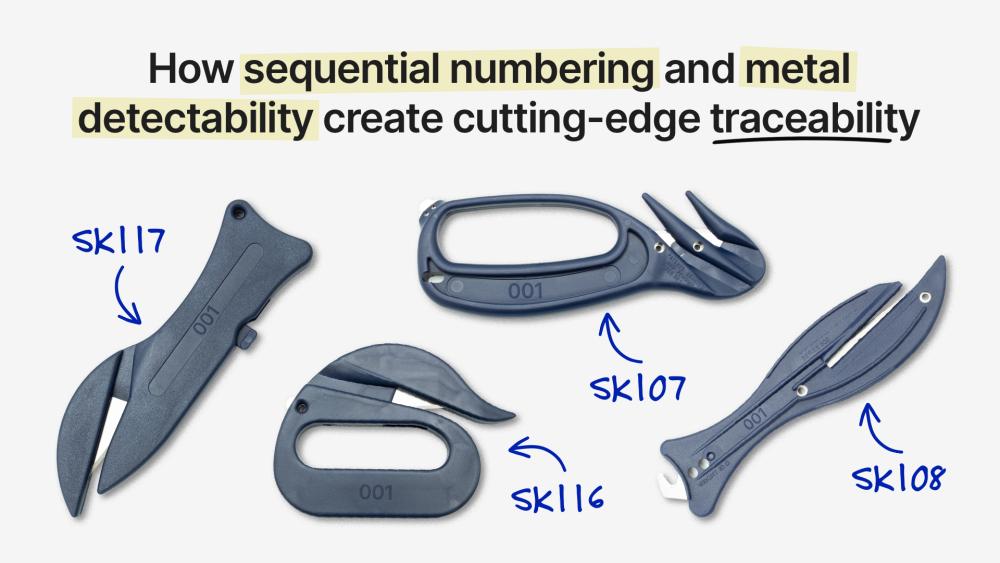

Metal Detectable & X-Ray Visible Products

Detectamet provides the world’s largest range of Metal Detectable & X-Ray Visible Products to 120 countries around the world and, many of these, can be pad printed and/or laser engraved with unique sequential numbers. From detectable pens, scissors, to retractable knives and beyond, these products are designed to be easily detectable by food safety systems, ensuring no foreign matter contamination enters the production line.

These products remain legible even in harsh production conditions, ensuring that sequential numbers are always visible and usable.

Customisation & bespoke solutions

Detectamet offers full customisation of its products to suit customer needs. Whether you need specific batch numbers, product SKUs or unique sequential coding, Detectamet can create solutions tailored to your traceability process. This customisation allows companies to track products at a granular level, from production to delivery, ensuring total oversight.

HACCP compliance & global standards

Detectamet's products support HACCP-compliant production processes. Sequential numbers on processing tools ensure that food processors can provide detailed production histories and traceability records for audits, inspections and regulatory compliance. These products are also FDA approved and meet the standards required by EU regulations, making them suitable for global food production environments.

Global supply & same-day despatch

With customers in over 120 countries, Detectamet offers fast, reliable access to sequential numbering products. Their same-day despatch service ensures processors receive what they need, when they need it, minimising production delays.

Why mix sequential numbering with detectable products?

Sequential numbering is powerful on its own, but when combined with Metal Detectable & X-Ray Visible Products, it becomes an essential tool for food safety.

By combining sequential numbering with Detectamet products, companies can:

- Trace and remove contaminated batches faster.

- Enhance product recall capabilities.

- Meet regulatory standards with dual protection.

- Provide total visibility across production lines.

It’s food safety in numbers with Detectamet

Food safety is non-negotiable and sequential numbering is a critical tool to ensure complete traceability, compliance and brand protection. By using Detectamet’s Metal Detectable & X-Ray Visible Products with sequential numbering, food processors can maintain oversight at every stage of production. Ready to strengthen your traceability processes? Explore Detectamet’s range of sequential numbering products today at www.detectamet.global

Detectamet USA (English - $ USD ) Click here to change your currency, region and language.

Detectamet USA (English - $ USD ) Click here to change your currency, region and language.